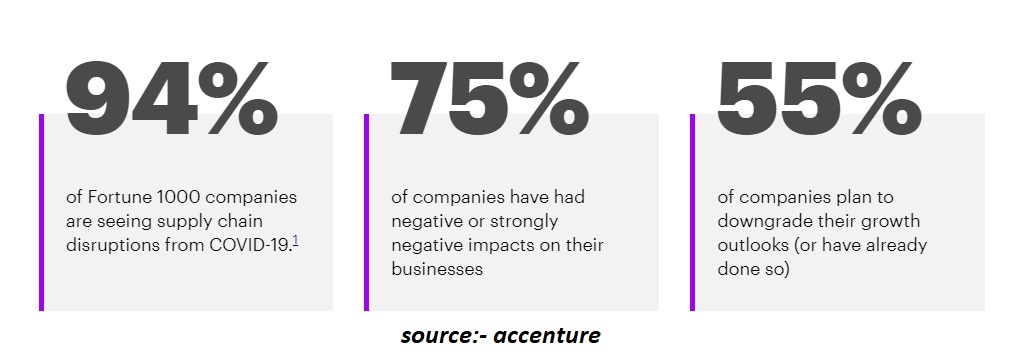

Most of us have been doing our part during this COVID-19 global pandemic, to keep up with the news about global response measures and have been working diligently to secure raw materials and components as well as protect supply lines.

The panic buying, empty shelves in the supermarket and shortage of the essential supplies are not the only disruption in the global supply chain due to the COVID-19 pandemic. Production stoppage across countries, shortage of raw materials as well as finished goods is the threat that is yet behind the curtain. The current outbreak is unprecedented in its scale and the government, as well as the medical professionals, are doing their best to get the hold of the situation.

The pandemic has resulted in an imbalance in the supply and demand structure. With lively hoods being at stake, businesses must respond on multiple fronts; protect their workers’ safety along with safeguarding their operational viability.

As COVID-19 spreads globally, we are seeing increased supply chain disruption, but also changes in consumer spending habits,” said Sarah Watt, senior director analyst with the Gartner Supply Chain practice.

While the damage is already done, here is how companies can pull up their socks and do the damage control! There are three impact areas to mitigate disruption; workforce, products and costs. Here’s why these areas are the most critical and how to manage them!

Impact areas to mitigate Disruption

1. Workforce

As social distancing has been strictly put to practise by local governments to limit the impact of COVID-19, employees are advised to stay at home, travel controls have been emphasised. These restrictions for manufacturing units have further resulted in failure to meet demands and not goods being exported to dependent markets. Such a situation results in a supply chain crisis.

Supply chain leaders need to be prepared and implement preventive strategies to protect the health of workers as well as support the ill. Implementing tight security and practising efficient communication through human resources is essential.

Since the crisis is ongoing, as per Gartner, the crisis management team becomes fatigued and makes poor decisions. It is the right team management and planning of resources that can help the workforce overcome the crisis.

2. Products

The pandemic caused by coronavirus has an impact that can change the competitive landscape. Suppliers are at risk, as the clients might start looking for alternatives when the suppliers fail to deliver the products on time. Products that receive a higher degree of brand loyalty might be impacted less during the short term as the customers are willing to wait for it. The consumer buying pattern might change; focusing more on essential goods, as the virus expands further.

When left with no other option than trade-off decisions, the impact of coronavirus must be analyzed and be taken into account. Products in demand with high-revenue as well as high-margin can be considered while doing a trade-off.

The organizations further need to constantly reassess their supply models based on the consumer behaviour due to the evolution of the virus. Furthermore, supply chains may experience crises and steep increase in demands due to panic buying.

3. Costs

Right from shipping to the shortage of raw material and labour, a variety of factors might be of concern for companies to meet their financial objectives.

The previously agreed prices and deals might no longer be valid. Force majeure, that means superior force as well as chance occurrence, unavoidable accident is a clause that could be invoked by the supplier to pass the additional costs.

Added expenses caused due to the pandemic should be treated as an issue for the whole organization than a single department. Such an approach makes it easier for the organization to weigh the cost against its ability to achieve objectives and manage stakeholder expectations.

It is a good practice to further prepare your organization for such occurrences in future. Analyze all supplier contracts and make the necessary changes that might aid the organization in future in such a crisis. This event has changed the supply chain industry; The industry will from now on be more focused on resilience, risk exposure and well as business continuity plans.