The supply chain is transforming at a drastic pace, as we foray into the future of a whole new shopping and mobility. In 2020 the Transport & Logistics industry and particularly, the supply chain is all set to get a technological overhaul in order to keep up with the constantly upgrading customer base and their subsequent expectations. In this read, we would discover five technological transformations that are going to change the face of the supply chain in 2020 and what the industry experts have to say about them.

Autonomous Trucking

Autonomous or self-driving trucks are expected to see a big boost this year. With companies like TuSimple, Uber and Waymo that are testing autonomous trucks on highways for months now, the day is not far when your parcel would be delivered by a truck with no one in the driver’s seat. Though it’s still a far-fetched thing, we are step closer closing on attaining Level 5 autonomy in trucking as major manufacturers are extensively working to upgrade their Level 4 autonomy tech.

“Bringing Level 4 trucks to the public roads is a major step toward our goal to deliver reliable and safe trucks for the benefit of our customers, our economies and society,” Daimler executive Martin Daum said in a statement.

Jason Gillespie, the supply chain director of continuous improvement for DHL says, “The technology is there and, I believe, fully capable. It’s exciting stuff. In these pilots, the driver doesn’t touch the steering wheel, the brake or the accelerator; they’re there just in case.”

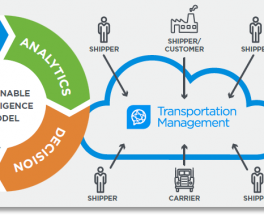

Freight matching – the digital way

Digital freight technology companies like Convoy, Uber Freight, uShip, XPO are using algorithms and real-time data and have created platforms that can find the best carrier for a shipper, taking care of different aspects like account cost, remaining service hours of the driver, location of the carrier and type of equipment. This has helped the carriers long way as they can now be matched with the most profitable freight available.

“Freight brokerage is critically important for streamlining logistics operations, but legacy systems and processes limit efficiency and make it harder to move more with less. “The new capability will help accelerate how carriers align their networks to the highest-yield markets,” said Hunter Yaw, vice president of product management and business development for Loadsmart.

AI taking over everything

With so much data that overflowing throughout the entire workflow of the supply chain, the integration of artificial intelligence is indispensable now. Today, most of the big names of the industry deploying AI on day to day operational basis such as identifying the best times to for social media posting and customizing the company’s website based on the specific market for each and every visitor. Artificial Intelligence would play a key role in the decision-making process of a supply chain firm in 2020.

Talking about the further inclusion of AI in the supply chain, Tom Curee, Vice President of strategic development at Kingsgate says, “We have so much data flowing at us now, and everyone is asking, ‘How do I mobilize this data? How do I make decisions from it?’ AI makes your data actionable. It’s not always making a decision for you; it’s helping you be able to make the decisions you need to make.”

Pop-up distribution centers

In e-commerce, the final leg of the supply chain can be the most challenging, especially when volume spikes and customers are left waiting for their parcels. DHL is using several pilot programs to explore how mobile technology can address this problem in dense urban settings. The concept is called a pop-up distribution center, and in this case, it’s basically a call for reinforcements.

The final leg or the last-mile delivery is the most essential part of the entire supply chain and this is more evident than before since customer expectations are skyrocketing. The concept came across to reduce the delivery time even further by using cars, motorcycles, or on foot delivery for last-mile delivery after the bulk packages have been dropped at the distribution center.

Robotic automation

Firms like DHL have already installed software in place to automate repetitive jobs like event tracking, collecting documents for proof of delivery, and load scheduling. This is done in order to reduce the rate of error and enhance the overall efficiency of the process. During the global test run of the project, DHL claimed to have saved more than 30,000 hours of manpower every year by achieving robotic process automation.

“Before RPA, many basic, day-to-day tasks would need to wait to be completed until capacity allowed. Now they are done quickly and with a high level of accuracy, freeing our employees to spend less time doing busy work and more time doing the strategic value-added work they enjoy” says Jim Monkmeyer, president of transportation for DHL Supply Chain in North America.