The supply chain industry has undergone a massive transformation in the past 3 decades. The supply chain function within a business ensures integrated operations in the entire ecosystem by all the stakeholders.

Challenges in Today’s Time in Supply Chain Management

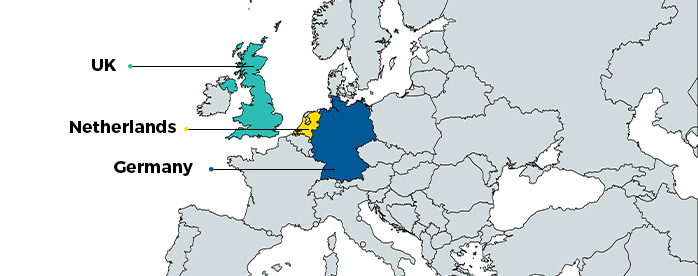

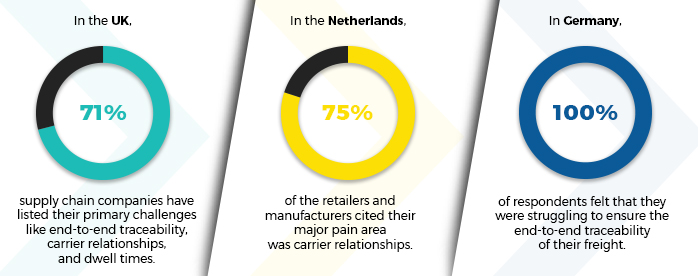

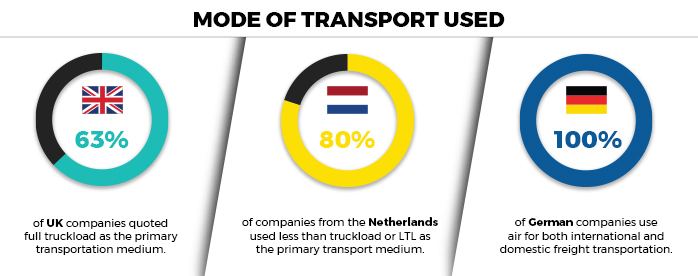

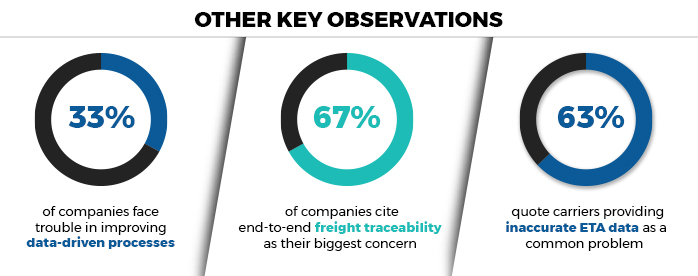

European supply chains have faced massive challenges due to the COVID-19 pandemic, including demand and labor shortages, unavailability of drivers, disruptions at the ports, and constraints related to their capacities, geo-political instabilities. However, few logistics and supply chain companies managed to counter these operational hurdles by successfully adopting supply chain visibility solutions. Conversely, over 60% of European organizations involved in supply chain management agreed they were laggards in reacting to these changes, as mentioned in the State of the European Supply Chain: Logistics, Sustainability and Visibility Report 2022*.

As per the report-

Digitization in Supply Chain Management – What it Means?

The Digitization of the supply chain is nothing but a formal transformation using digital technologies. Digitization is important as it optimizes the supply chain ecosystem by addressing the key challenges and introducing “Supply Chain 4.0”, which is faster, more accurate, more efficient, giving higher predictability and accelerated growth. Supply chain solution providers like DiLX have played a crucial role in digitally transforming the supply chain, ensuring seamless logistics operations, which has created a phenomenal impact. Digitization of the supply chain focuses on the core 3 areas- data management, process integrations, and reduction of mundane manual processes.

- Digitized Data Management: Data management software accurately captures huge volumes of data. This data is then used to automatically receive orders from stores, process them for fulfillment, update the stock levels, and maintain the real-time inventory status.

- Improved Process Integration: The use of various supply chain technologies has been designed in a way that they can be easily integrated, thus creating an end-to-end supply chain solution. Integrating key processes leads to better transparency and synchronization among the supply chain stakeholders.

- Use of Digital Tools for Reducing Manual Processes: Digitization of the supply chain also directly impacts how various manual processes are executed. Data related to the location of inventory also plays a crucial role in enhancing the overall supply chain efficiency. Nowadays, warehouse and inventory bots have taken over various on-floor tasks like transporting items within the warehouse and assisting in retrieving items for faster fulfillment of orders.

How Digitization of Supply Chain Becomes Beneficial?

Digitization has benefitted the supply chain by elevating overall efficiency and performance. Digitization assists in improving the supply chain execution and planning, which yields the following benefits-

- Better Financial Management: Digital inventory management is a key component in the supply chain, giving real-time visibility to all inventory activities. This helps in managing the financials in a better manner. With digital solutions, supply chain managers can plan their inventory refilling more accurately, reducing unnecessary cost overheads and any risk of “dead or perished inventories.”

- Reduced Lead Times: With real-time visibility of processes, digitization helps supply chain managers shorten their lead times and improve supply chain visibility. Digitization also assists in eliminating the manual work along various supply chain departments, which goes a long way in speeding up key processes.

- Improved Decision Making: The correct supply chain tech stack can be useful for obtaining key information for improved decision-making, owing to advanced tracking and analytics capabilities. Certain technological solutions are used to predict future demand, which helps plan inventory levels to improve delivery turnaround times and save costs.

Supply Chain Sustainability – What is It & Importance

There has been a significant rise in the number of companies that are shifting their focus toward sustainable supply chains. The major reason driving this transition is the recent rising legislation centered around supply chain visibility and increased customer demand for sustainable products.

The supply chain is considered sustainable when it uses environmentally and socially sustainable practices at various stages to secure its people and the environment across the entire supply chain. This means that a supply chain organization supports environmental and social standards for its core operations and suppliers. For supply chain organizations, social sustainability must be equally important as environmental sustainability.

Importance of Sustainable Supply Chain

- Addressing the Demands of Customers & Investors: One major reason for focusing on the sustainable supply chain is that consumers are now more aware of various unethical practices sometimes used in many supply chains. With consumers being informed about such unethical issues, they prefer to use products from companies that proactively manage and balance their supply chains’ social and environmental impacts. Investors also nowadays look to make more investments that are social and environmental. They know about the reputational and financial risks of companies that follow unsustainable practices in their supply chain and may not be willing to invest in such organizations.

- Developing Resilience in Supply Chain: A sustainable supply chain also helps in building supply chain resilience during unforeseen times. When the employees and workers suffer from the negative implications of environmental degradation of a company, it directly affects the workforce’s availability, ability, and resilience on which the supply chain is completely dependent.

- Increasing Climate Changes and Global Disruptions: The present-day customer is well aware of the negative environmental implications of the supply chain with whom they have bought products and services. The long-term effects of climate change are calamitous for both the planet earth and its people, and consumers are smart enough and always look to support businesses that are looking to make a more sustainable world. The impacts of a bad workplace can be seen inside and outside the organization, and pollution and noise can cause health deterioration in the workers. Thus, manufacturers must create a sustainable supply chain that benefits everyone alike.

- Growing Legislation Concerns: Many countries have developed supply chain sustainability legislation. Under this, businesses are required to demonstrate and report their supply chain’s due diligence. For instance, the EU countries that are importers of tin, tungsten, and tantalum and their ores need to provide reports on the supply chain due diligence obligations owing to Conflict Minerals Regulation established in 2021.

DiLX is Coming to the Transport Logistic Event

DiLX is glad to announce that our Team of Digital Transformation Experts will be there at the Transport Logistic Event at Trade Fair Center Messe Munich, a leading supply chain event for logistics, mobility, IT, and supply chain management.

Get a chance to meet our experts, who have over five decades of combined experience. They will be there at this digital supply chain event to answer all your queries and concerns that you might be encountering in your daily supply chain operations. Meet our Team at Stall No #435, who’ll be there from 9:00 AM to 6:00 PM, and discuss the future supply chain business growth opportunities with DiLX.

To know more, visit – https://www.dilx.co/